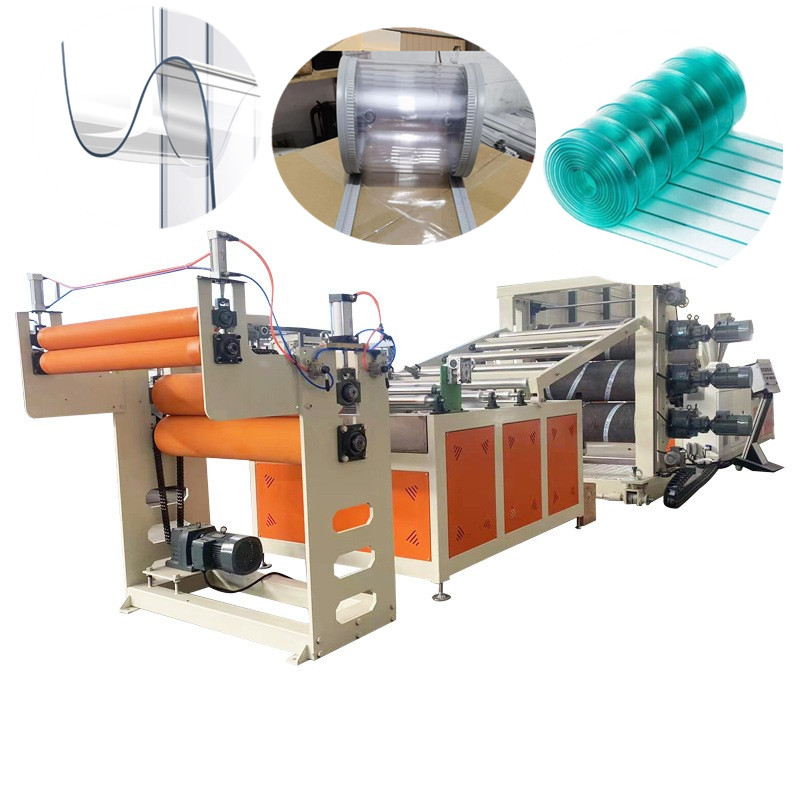

A extrusion system

* Screw diameter: 65 / 132 (Zhoushan, Zhejiang)

* Design maximum output: 180-200 Kg / H

* The screw structure is designed for PVC powder in the form of conical rotation.

* Screw material 38CrMoAlA nitride, desalination depth 0.5—7mm, surface hardness HV 940

* Cartridge heating system cast aluminum heating ring + stainless steel cover

* Cooling mode The fan has forced cooling

* Heating area number 5 area, heating power of 26KW,

B Quantitative feeding system

* Use the stainless steel feeding hopper

* Power of the feeding motor: 1.1KW

* Speed regulation mode of the feeding system: frequency conversion speed regulation

C, vacuum pumping system

1. Power of the vacuum pump: 2.2KW

2. Vacuum degree: 0- -0, and 7Pa

D, drive system

1. Adopt high torque speed reduction box, low noise and long life (Jiangyin, Jiangsu)

2, reducer gear material 20CrMoTi, gear using oblique tooth surface combination,

3. Distribution box: single axis torque output into double axis torque output through super-bical gear

E, Main motor system

1. Main motor power: 37KW (Shandong Kejie or Shandong Xian motor)

2. Main motor speed regulation mode: AC frequency conversion control

F, electric control system

1. Unique designed electrical control cabinet

2. Chint low-voltage electrical appliances

3. Intelligent temperature controller

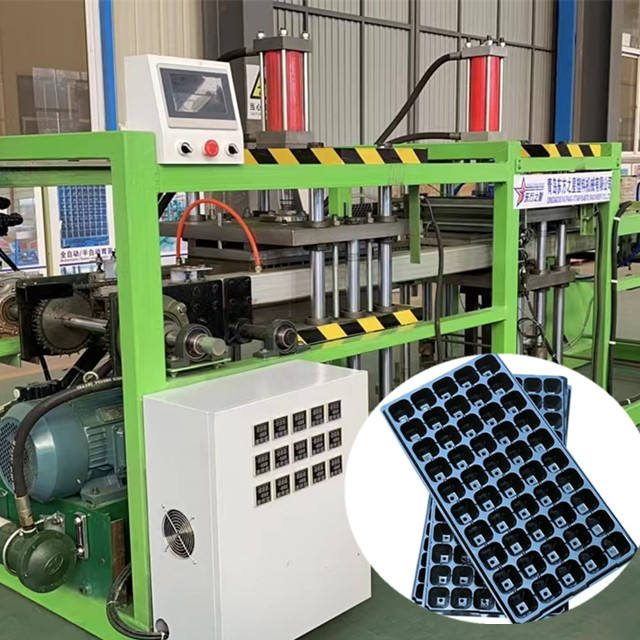

* Screw diameter: 65 / 132 (Zhoushan, Zhejiang)

* Design maximum output: 180-200 Kg / H

* The screw structure is designed for PVC powder in the form of conical rotation.

* Screw material 38CrMoAlA nitride, desalination depth 0.5—7mm, surface hardness HV 940

* Cartridge heating system cast aluminum heating ring + stainless steel cover

* Cooling mode The fan has forced cooling

* Heating area number 5 area, heating power of 26KW,

B Quantitative feeding system

* Use the stainless steel feeding hopper

* Power of the feeding motor: 1.1KW

* Speed regulation mode of the feeding system: frequency conversion speed regulation

C, vacuum pumping system

1. Power of the vacuum pump: 2.2KW

2. Vacuum degree: 0- -0, and 7Pa

D, drive system

1. Adopt high torque speed reduction box, low noise and long life (Jiangyin, Jiangsu)

2, reducer gear material 20CrMoTi, gear using oblique tooth surface combination,

3. Distribution box: single axis torque output into double axis torque output through super-bical gear

E, Main motor system

1. Main motor power: 37KW (Shandong Kejie or Shandong Xian motor)

2. Main motor speed regulation mode: AC frequency conversion control

F, electric control system

1. Unique designed electrical control cabinet

2. Chint low-voltage electrical appliances

3. Intelligent temperature controller