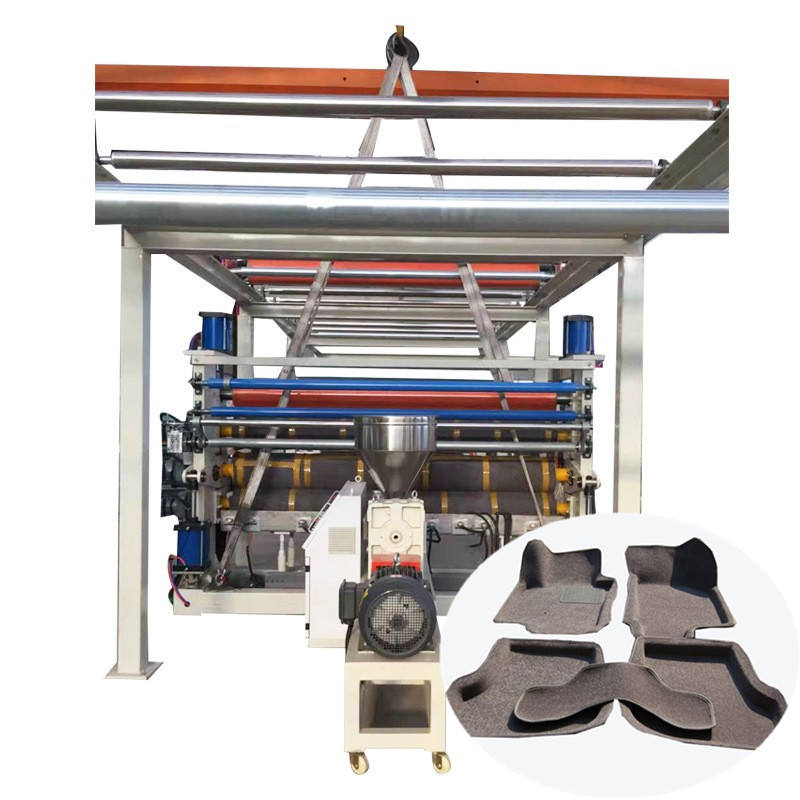

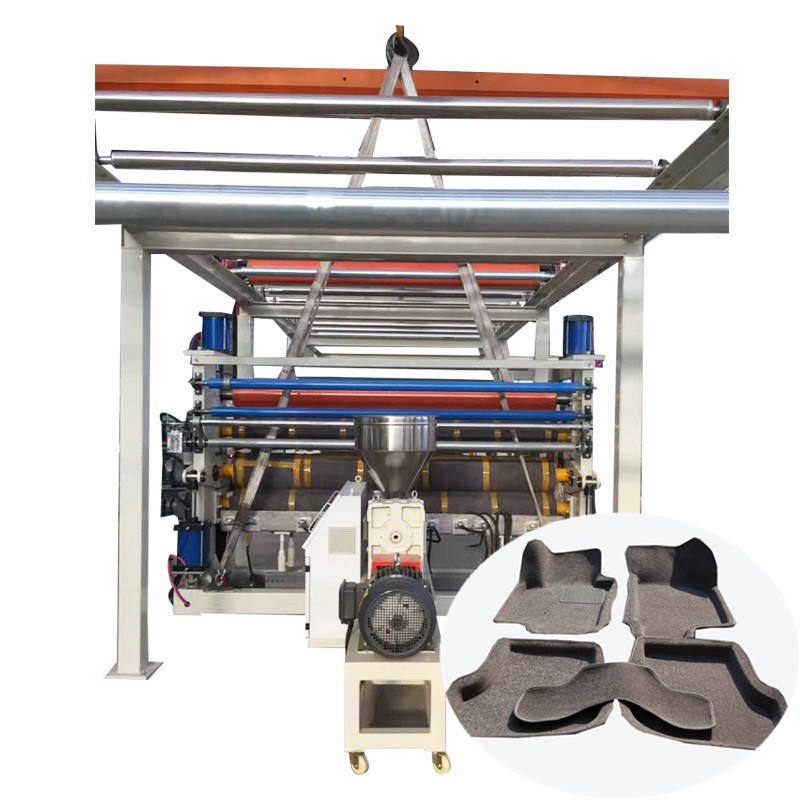

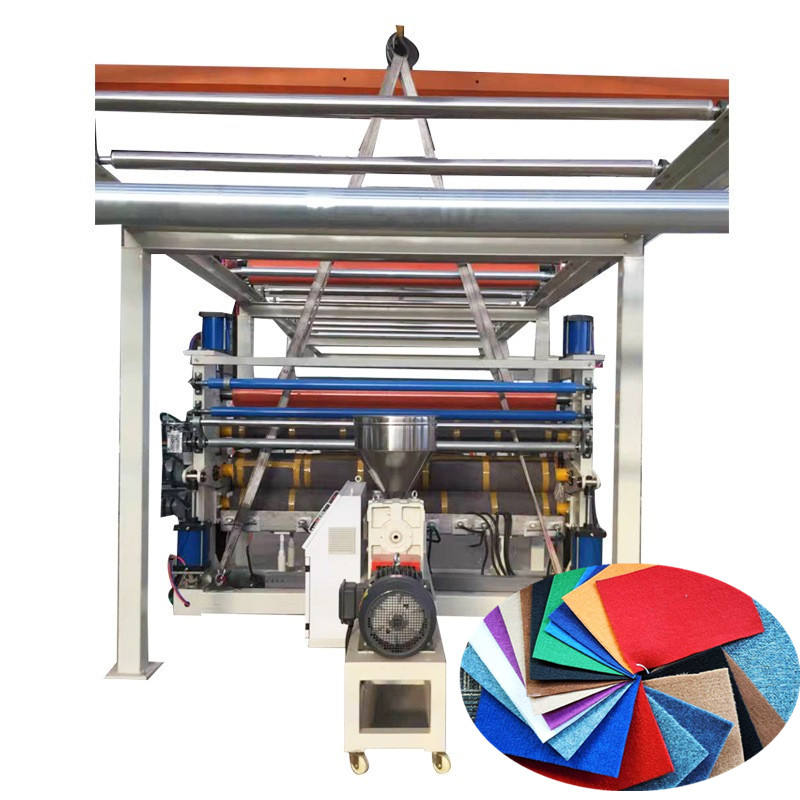

SJ45-30/1 Extruder

1 High torque hard tooth surface reducer Gear fine grinding processing, low noise

2 Double alloy screw barrel 38CrMoAL Nitriding

3 Main motor power 11KW,3P alternating current motor

4 Screw speed 10~70 Rotate/Minute

5 Diameter of barrel screw Φ45,L/D 1:30

6 Number of heating rings (cast aluminum) 3 groups:each 3KW

7 Cooling Type of barrel air cooling,air blower3×0.18KW

8 Feeding type Stainless Steel Hopper

9 Temperature controller and temperature sensor Omron digital temperature control meter

10 Frequency conversion speed regulator 11KW frequency changer

11 Contactor Schneider or Siemens

12 Other Low Voltage electric Delixi or Zhengtai

13 Frame construction Welded Steel ,thickness above 8mm