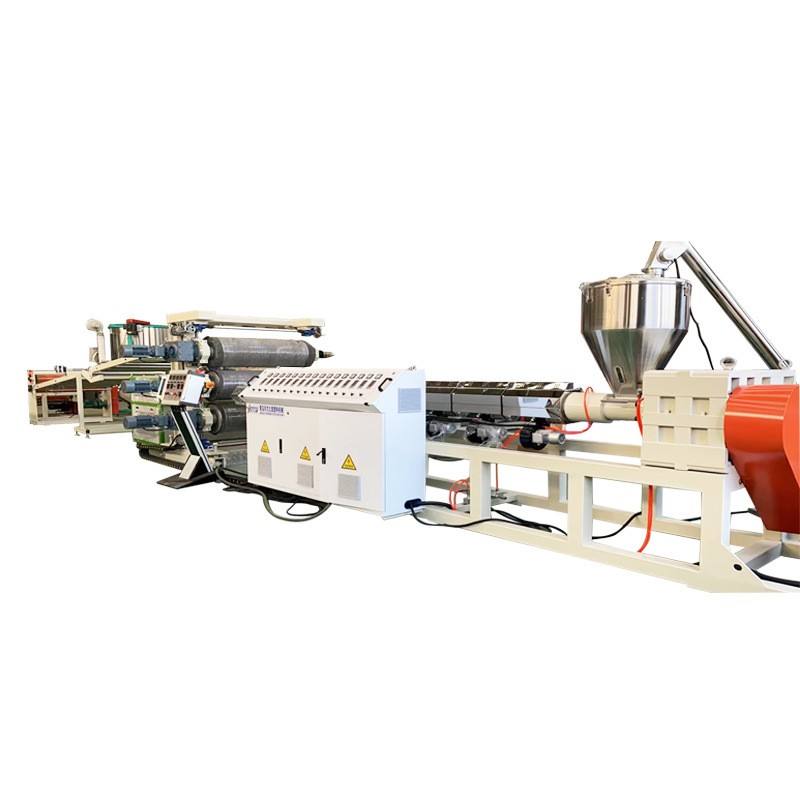

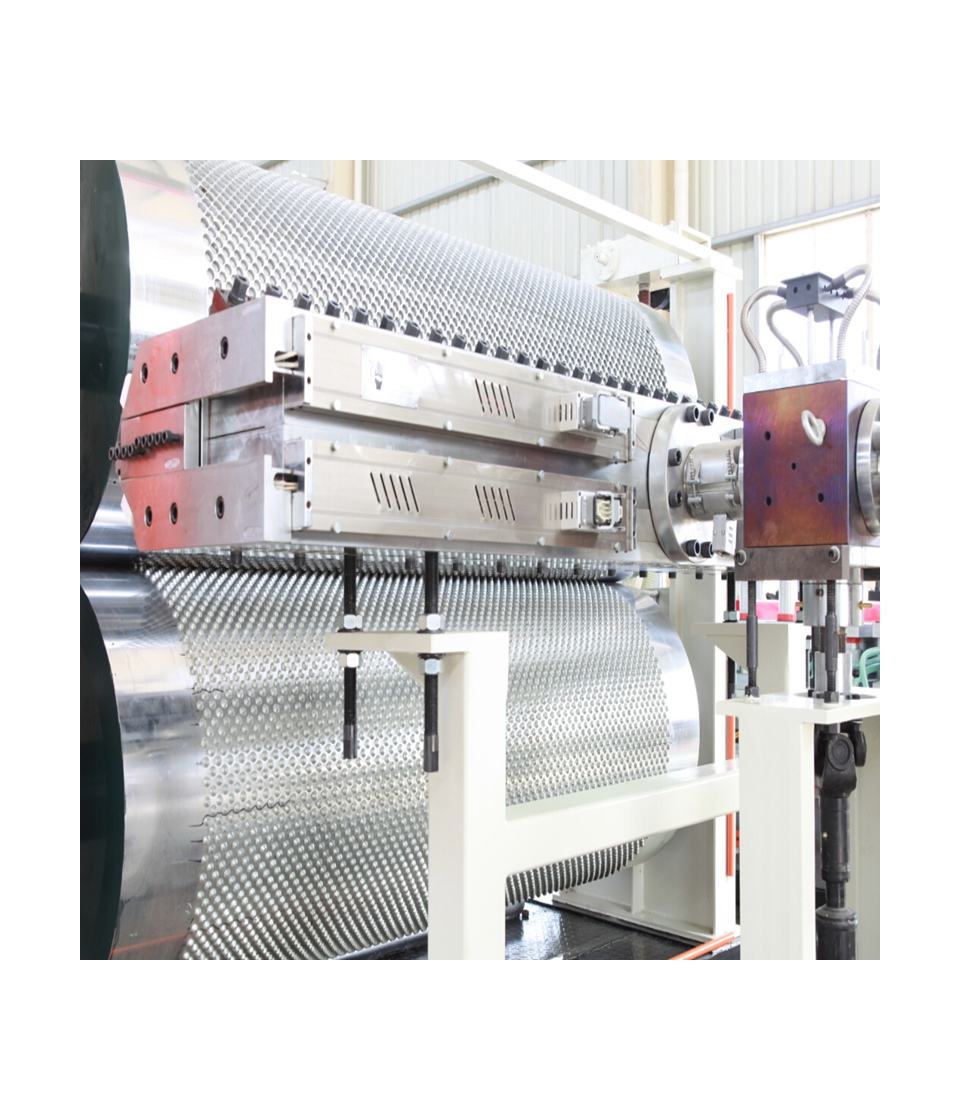

SJ-120-30 / 1 extruder (reducer using Changzhou long reducer, screw cylinder using Zhejiang Jinxing or

Golden Teng screw, frequency converter using Shenzhen Flextron, temperature controller using Japan Omron, contactor using Siemens)1. The reducer gear is processed with high quality alloy steel and grinding, which has the advantages of shock absorption, low noise, wear resistance and long service life. All the lubrication points in the box are forced lubrication, and the lubricating oil is equipped with high efficiency water cooling system.

B, screw material adopts 38CrMOALA high quality nitride steel, and nitride treatment, nitride depth: 0.3-0.6mm, hardness 740 HV,

brittleness grade 2.