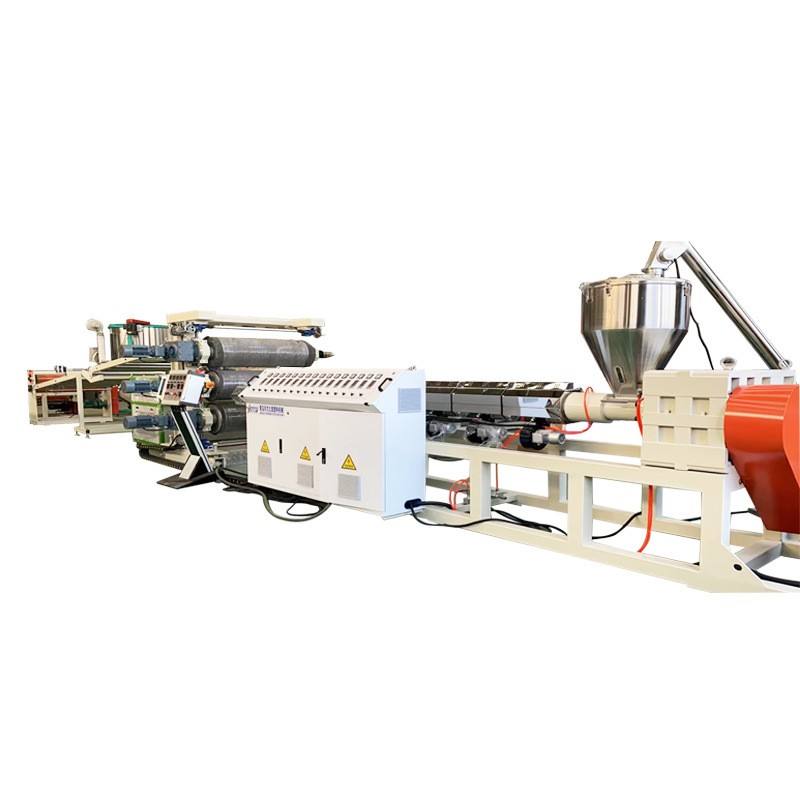

SJ-150 / 35 single screw exhaust type extruder parameter

Screw barrel Zhejiang Zhoushan

material quality 38CrMoAIA

depth of nitration 0.5-0.7mm

Screw hardness ≥HV740

Machine cylinder hardness ≥HV940

Screw diameter Φ150mm draw ratio 35

Bottle heating method Ceramic heating

Number of heating areas 9 District

Heat the total power About 70Kw

cooling-down method Fan cooling

cooling power 9×0.25kw