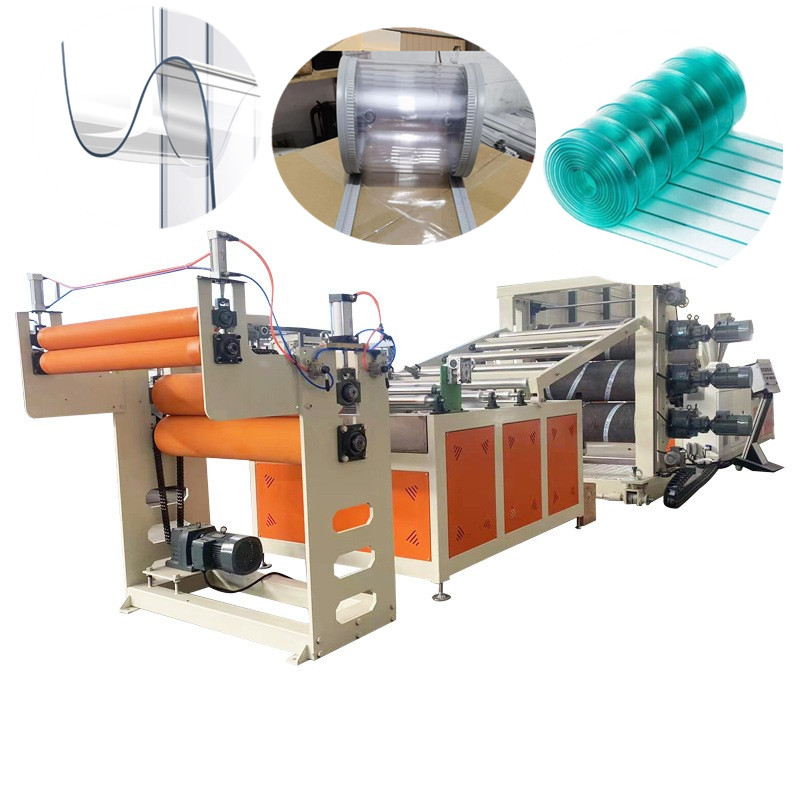

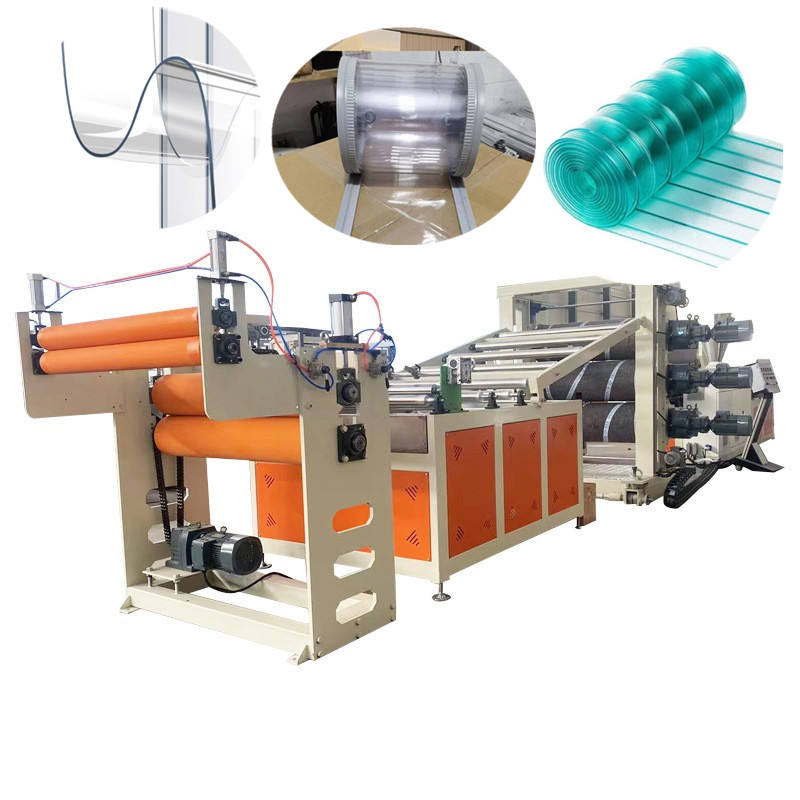

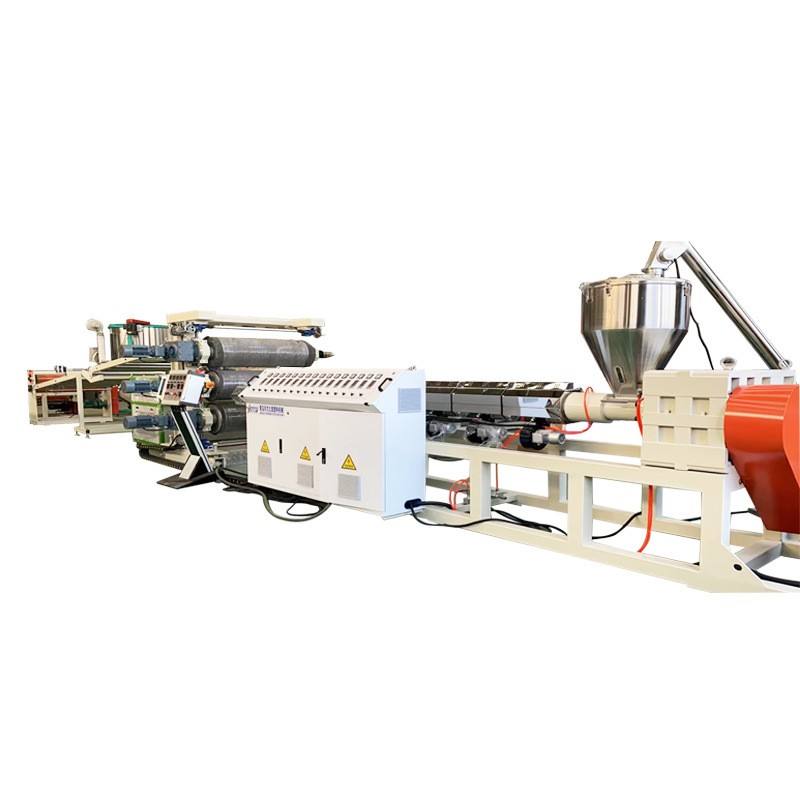

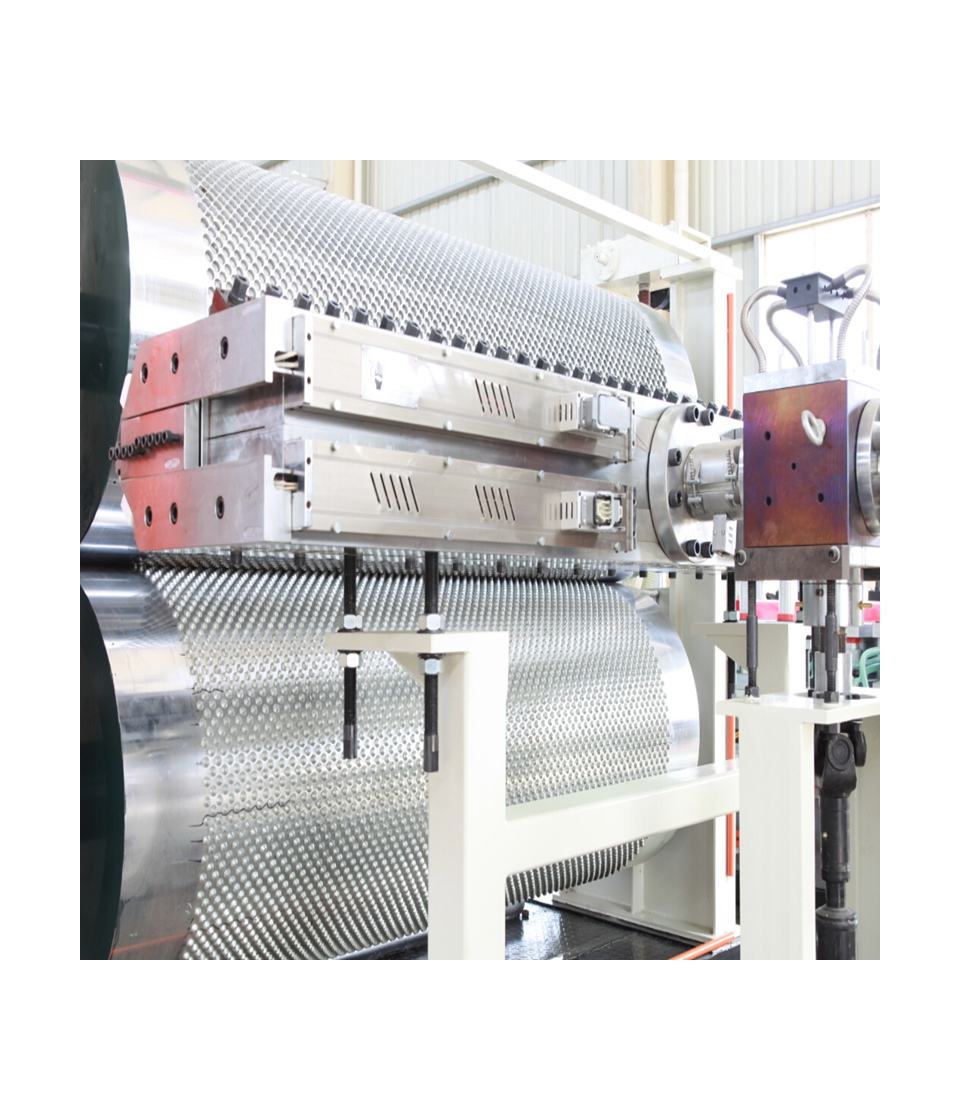

can produce PVC transparent plastic sheets with a width of 800-2000 mm and a thickness of 0.8-6 mm. The equipment adopts SJ120 or SJ-150 single-screw extruder, T-type elastic die mouth adjustable mold, vertical or 45-degree inclined three-roller calender, three-in-one water temperature machine, stainless steel cooling bracket and wide Adjustable width trimming knife, rubber roller traction machine, double-station air-expanding shaft winding machine. The production line adopts three-dimensional electric control cabinet: intelligent temperature control system, Siemens low-voltage electrical appliances, and frequency conversion speed regulators of well-known brands at home and abroad. The sheet produced has a shiny surface, is transparent, flawless, soft, has no cracks, no odor, no bubbles, is finely made, and is widely used; it is soft, cold-resistant, wear-resistant, acid-alkali-resistant, corrosion-resistant, and tear-resistant, and can be welded. Resistance, physical properties are better than other coiled materials such as rubber; used in chemical industry, electroplating, electrolytic tank lining, insulating cushion, train, automobile interior and auxiliary materials; the working temperature range is from minus 15 degrees Celsius to 60 degrees Celsius, and can be bonded ,welding. Easy to clean, in line with modern people's green, healthy and fashionable requirements.